SERVICES

Rapid Prototyping and Product Development

At Centracore, LLC, we specialize in delivering fast and reliable rapid prototyping services to support the product development needs of our customers. We understand the importance of turning ideas into functional prototypes quickly, which is why we offer flexible solutions that help bring your concepts to life in just weeks, not months.

Our Prototyping Capabilities

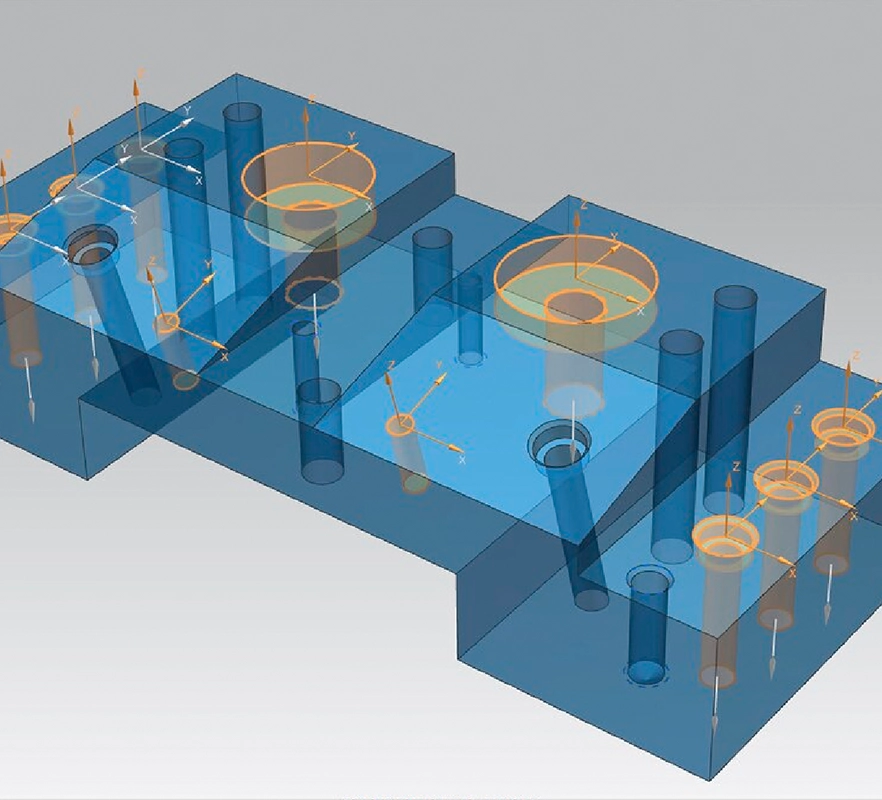

Centracore offers several advanced methods for rapid prototyping, allowing us to produce high-quality parts that meet a wide variety of needs. Our prototyping services are available for different applications, from automotive parts to more specialized designs. The key processes we use include:

- High Pressure Die Casting: Perfect for creating complex parts with high detail and consistency. This method is ideal for producing functional prototypes that are close to final production quality.

- Low Pressure Molding: Offers smooth surface finishes and is suitable for parts requiring a higher level of precision.

- No Bake Sand Casting: Provides strong, durable prototypes with excellent dimensional accuracy.

- Green Sand Casting: A cost-effective solution that’s suitable for rapid prototyping with a variety of material options.

- Investment Casting: Allows the production of intricate designs with fine detail, ideal for small to medium batches.

- Plaster Casting: Produces high-precision, small-volume prototypes, perfect for specialized components.

- Extrusions: Offers continuous shapes and profiles, ideal for parts needing specific dimensions.

- Forging: Particularly beneficial for prototypes that require strength and resilience, commonly used in automotive applications.

- Machining from Billet: For high-precision prototypes where material integrity is crucial.

These methods provide flexibility in terms of material selection and the types of prototypes we can produce. After the initial prototype is created, we can also perform secondary operations, including additional machining, surface treatments, and assembly. Parts can be supplied in various forms, such as “as cast,” “as forged,” or “as extruded,” based on customer specifications.

Rapid Prototyping in Automotive Applications

Centracore is proud to serve the automotive industry, where rapid prototyping plays a crucial role in accelerating development timelines. Our prototyping processes are made to meet the specific needs of automotive manufacturers, making sure that prototypes are delivered quickly without compromising on quality.

Our rapid prototyping automotive solutions are designed to facilitate faster testing, iteration, and validation of new designs. By using advanced casting, molding, and machining techniques, we help automotive manufacturers move from initial concept to functional prototype in a fraction of the time it would typically take using traditional methods.

Why Choose Centracore for Rapid Prototyping?

Centracore’s rapid prototyping services stand out because of our commitment to quality, speed, and customer satisfaction. With a wide range of prototyping methods and a dedicated team of experts, we are well-equipped to handle your prototyping needs, whether they are for the automotive industry or another sector.

Our quick turnaround times, coupled with our ability to produce prototypes from a variety of materials and methods, allow us to provide solutions that meet your needs, all while keeping costs competitive. With Centracore, you can trust that your project will be in capable hands from start to finish.

Contact Us Today

Ready to get started on your next rapid prototyping project? Contact us today to discuss your requirements and receive a quote. Our team is here to help bring your ideas to life quickly and efficiently.